DESIGNING SUSTAINABLE TECHNOLOGIES

Our sustainable technology solutions transform natural resources into innovative products for industries ready to embrace the future.

SOLUTIONS

Nitrogen

We have a proprietary technology portfolio which is considered the leading and most efficient one in the production of various fertilizer technologies from Urea to Nitrates, providing solutions for agriculture industry.

Hydrogen & Circular Carbon

We enable the decarbonization of industries and energy sector through the valorization and utilization of captured CO2 and the implementation of technologies to produce cost-effective, clean and green hydrogen.

Fuels & Chemicals

As long-term leaders in hydrotreating and hydrocracking, we are now applying our expertise to develop bio-based fuel and SAF as well as Syngas for methanol, ethanol and e-fuel, to decarbonize transportation sector.

Polymers

Our technology offering for plastic manifacturing industry is extensive and comprehensive: Plastic Upcycling, Chemical Recycling, and Biodegradable and Compostable Polymers.

RESEARCH & DEVELOPMENT

We are committed to translating market expectations into more effective technological solutions in terms of performance, cost and environmental sustainability. We do this through an integrated approach of internal scouting, collaboration with the most advanced European Universities and Research Centers and the validation together with the assessment of innovative technologies at the pilot level.

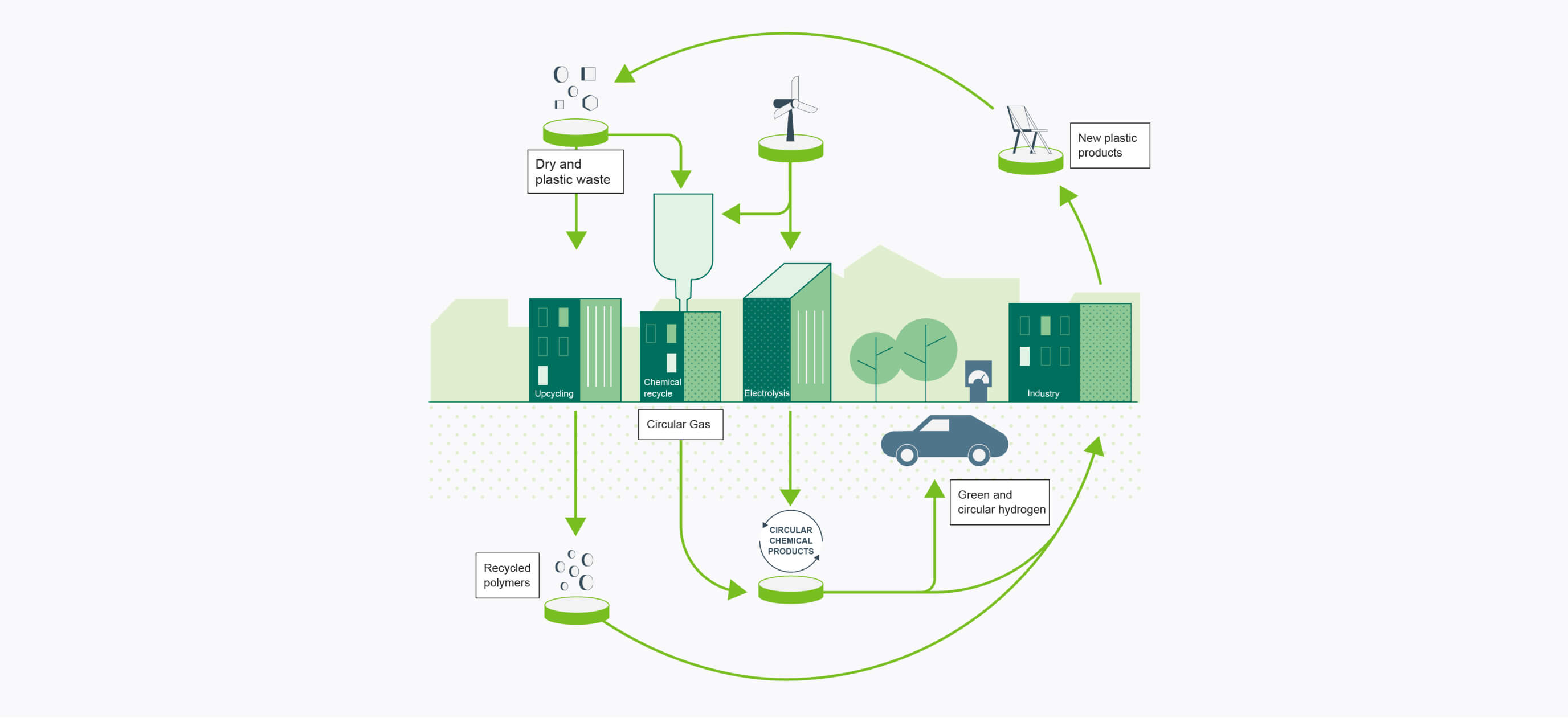

GREEN CIRCULAR DISTRICT

We came up with a solution that combines our technologies to offer low-carbon products that are essential for industry and mobility.